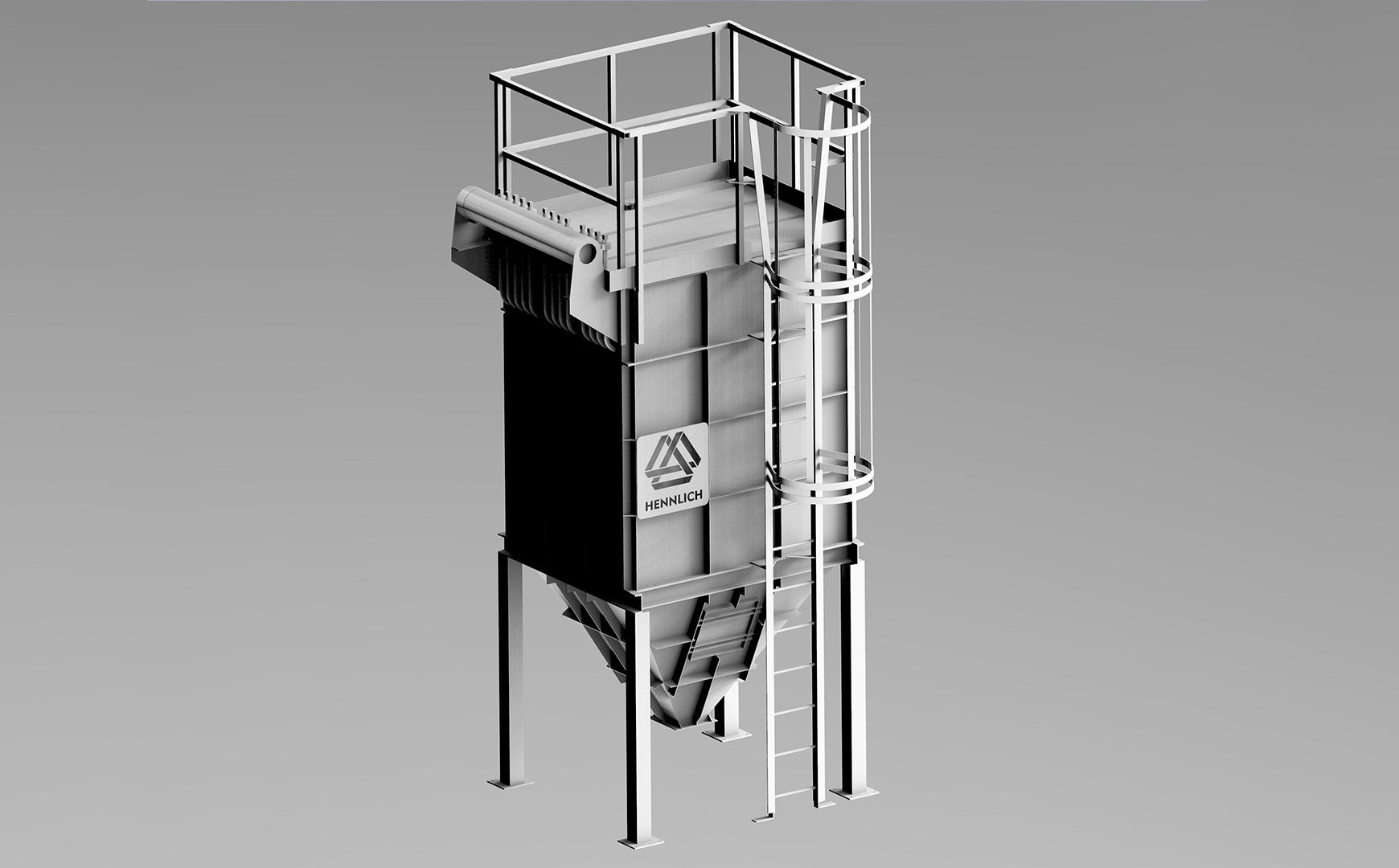

Ceramic dust collectors

Filtration units designed for dedusting hot flue gases containing sparks and hot particles. These are filter units equipped with high-temperature resistant ceramic filter inserts with a melting point of 1200 °C.

These ceramic filters are equipped with automatic regeneration using compressed air. Filtration efficiency – over 99 %.

Dedusting volumes from 1.000 up to 15.000 m3/h.

The ceramic dust collectors are designed for dedusting flue gases generated by the combustion of solid fuels in combustion sources. Thanks to their construction, the dust filter are used for dedusting biomass combustion boilers.

The basic characteristic of filtration units is the resistance to hot particles and residues of unburned fuel which occurs in the flue gases during the combustion of biomass.

The flue gases entering the filter unit are directed to the lower part of the filter device by means of an internal partition so that the housing of the filter unit is evenly heated. The flue gas passes through the filter medium upwards into the clean filter chamber and then through the outlet opening to the flue gas fan.

Ash collection takes place in the standard design into integrated ash tanks which the boiler operator periodically empties. For boilers in continuous operation, the filter units are to be equipped with an automatic ash removal system. At lower installation heights the removal of dust is solved by means of a movable bottom of the filter and then by a screw conveyor to the dustbin.

The filtration device is thermally insulated over the entire casing and is equipped with an electric heating cable for tempering the filter housing and preventing condensation of flue gases at the moment of starting or stopping the boiler at a low flue gas temperature.

The filtration equipment does not have to be equipped with a pyramidal dust hopper due to the lower installation dimensions for the possibility of installation directly into the boiler room.

Main applications

Dedusting of biomass boilers

Dedusting of coal boilers